K2 Engineering Industrial Software and Solutions

K2 Engineering Industrial Software and SolutionsAutomated Network Sizing (ANS) An AFT Fathom Add-on Module

Automated Network Sizing (ANS) An AFT Fathom Add-on Module

numerical searching algorithms and pipe flow simulation. The technology

was developed by AFT and has been a solution proven to save capital

costs. It evaluates the complex interaction of variables in your

system design, revealing combinations of parameters

that minimize cost.

Why Use the ANS Module?

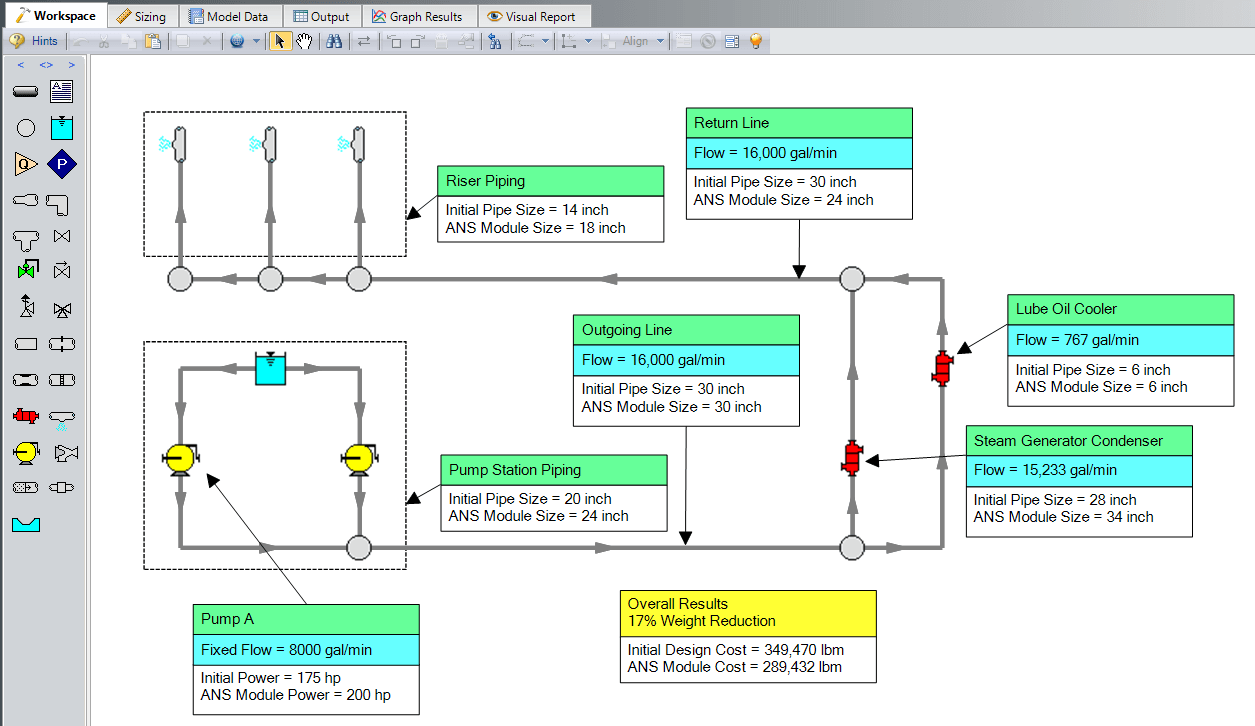

Gone are the days of sizing each line individually. Automatically size all piping and system components in an integrated manner to minimize weight and cost. This is done using advanced numerical searching algorithms available in the ANS module.

The benefit to engineering design firms is that they can significantly reduce the costs on piping. Experience shows this reduction is typically 10-15%.

Further, if design firms so choose, they can also directly minimize monetary cost of the entire piping system based on initial cost or even recurring costs!

Empower Engineers to Design for Tomorrow with Advanced Sizing Technology

- Size pipes to minimize pipe weight, duct volume, or system monetary cost

- Input design requirements such as pressure, flow, velocity or NPSH to guide the automated sizing process

- Reduce pump energy usage

- Assign sized pipes and pumps to groups to enforce commonality of automated size selections

- Automatically size pipes, pumps and valves to satisfy requirements across multiple design cases organized into different scenarios

- Employ industry-leading searching algorithms to find the best sizing result

- Easily import piping and equipment costs from Excel

Save 10-15% on piping costs and energy costs!

Benefits:

- Capital cost savings

- Minimize the initial and life cycle cost of your system designs

- Achieve inherent system flow balance

- Ensure performance requirements are met over multiple design cases

- Understand what really drives your design

- Users familiar with AFT Fathom will be able to utilize the ANS module with little additional effort

The extra effort to perform automated sizing on an AFT Fathom model is as little as 1%

How it Works

Simply follow the Sizing Navigation Panel to:

- Sizing Objective: Select whether to minimize weight, volume or cost (this will determine your navigation path)

- Size Assignments: Identify individual pipes, or common groups of pipes to be sized

- Candidate Sets: Choose the range of allowable pipe sizes

- Design Requirements: Input and apply design requirements to the appropriate pipes and junctions

- Assign Cost Databases: (optional) For cost-based sizing, select the cost data for the piping and equipment

- Sizing Method: Select an algorithm to use, or just follow the default choices

- Dependent Design Cases: Select multiple operating cases you would like to include in the sizing

Intelligent System Sizing for Incompressible Piping Systems

|

It is a software tool used to intelligently size piping and ducting systems to minimize cost. It offers a dramatic improvement to the traditional design process. Built on the advanced flow analysis and system modeling capabilities of AFT Fathom, it can simulate your piping system in complete detail.

Designed for fluid systems containing:

- water

- petroleum and refined products

- chemical products

- cryogens

- refrigerants

- low velocity gases

- and more

It is particularly useful for:

- Minimizing the initial cost of your system

- Minimizing the life cycle cost of your system

- Meeting specific design parameters of your system including minimum pipe weight, volume or surface area

Achieve Significant Cost Savings in Your System Designs

- Automatically sizes piping, ducting, pumps, valves and other components to achieve your cost goals

- Provides a comprehensive approach to identify low cost design of real world systems that is rarely practical with traditional methods due to the large number of variables and constraints involved

- Provides the power of informed decision making when developing a low cost system design

Features

- Advanced optimization engine with IntelliFlow® technology to automatically determine the best possible pipe and equipment sizes

- Comprehensive system modeling capabilities

- Scenario Manager to track all design variants and operational possibilities in a single model file with data linkage

- Integrated graphing and reporting

- Conduct thermal analysis including piping heat transfer and heat exchanger modeling

- Supports Newtonian and non-Newtonian fluids

- Built-in library of fluids and fittings can be extended and customized

- Optional Chempak add-on utility provides a thermophysical database of almost 700 fluids

World Class Support

Your software purchase includes a free year of product upgrades and technical support provided by our team of professional engineers. More than software support, Applied Flow Technology provides the pipe flow analysis knowledge that comes with extensive real world experience.